Speedmark Polymers was established in 2011, initially focused on FRP and thermoplastic repairs and maintenance. During 2012 Speedmark acquired the industrial manufacturing unit of Amitech South Africa, a subsidiary of the Saudi-Arabian based Amiantit. The acquired pieces of plant and equipment include a large diameter filament winder (150mm to 5 500mm) and a double axel pipe winder (25mm to 300mm), allowing Speedmark to become a niche manufacturer of FRP composite equipment. Our company has since shown significant growth and we have either directly or as subcontractors delivered components and field services to some of South Africa’s foremost companies, including AngloGold Ashanti, Omnia, Amplats, Impala Platinum, Sasol, Eskom, Plascon and AECI.

Speedmark, acting as local contractor for Turkey’s Aşut’ Fiberglass is also responsible for all on-site manufacturing and installation activities relating to the FRP spray banks and process piping for the flue gas desulphurisation plant at Eskom’s new Kusile power station.

Speedmark’s vision is to become the pre-eminent supplier of technologically advanced FRP solutions in Sub-Saharan Africa.

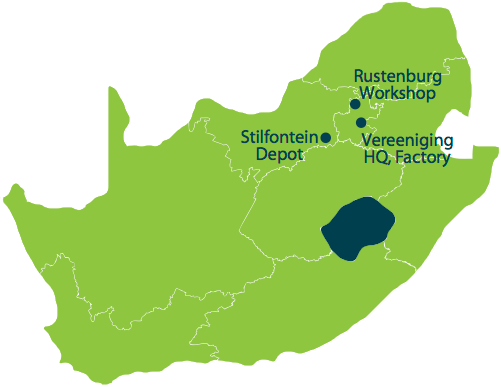

Our geographic footprint ensures a client-centric approach and consists of the following facilities:

Speedmark currently holds a TRMS (independently recognised authority on non-metallics) quality rating. We are working closely with TRMS to develop our quality control system further and have a medium term goal to achieve ISO 9001 & 14001 accreditation. Speedmark works closely with your engineering team to select the most appropriate resin and reinforcement materials to meet your individual corrosion resistant requirements and project specifications. We maintain strong relationships with premium grade resin and reinforcement suppliers and manufacture only with certified and tested raw materials. All manufacturing activities and field services are governed by and executed in line with international standards and best practices.

Our level 4 BBBEE rating ensures a 100% procurement inclusion rate for your organisation.

Speedmark values external awards as this provides an independent endorsement of our internal processes. Speedmark is proud to announce the recent achievement of the highly sought after green safety compliance code from Sasol Limited.

Safety is non-negotiable, and Speedmark has implemented systems to manage and measure operational risks throughout the organisation. Speedmark’s operations comply with the Republic of South Africa's Occupational, Health and Safety Act No. 85 of 1993 and Mine Health and Safety Act No. 29 of 1996.

Training is focused on the safe execution of all activities, whether factory or office based or on a site, and the commitment to this is driven from the top of the company.

The health and well-being of all employees are considered extremely important, and education forms a vital component ensuring that all have access to information.

Speedmark focuses on the use of environmentally responsible best practice and its strong environmental management policies underscore its commitment to ensuring the maintenance of a healthy and sustainable environment.

Speedmark’s shareholders and management support the principles contained in the Code of Corporate Practices and Conduct as set out in the King Report on Corporate Governance for South Africa 2002 (King II). All business transactions are conducted in an open and transparent manner with accountability levels benchmarked at international best practice standards.

Risk management remains a core driver within Speedmark and the company’s systems are focused on identifying risks within both the organisation and individual projects and mitigating against these. The company is committed to best practice risk management methodologies and this strategy filters through all processes and procedures.

Systems benchmarked against industry best practice are used and highly skilled and experienced people are tasked with building detailed project plans prior to project commencement. Speedmark has a strong ethos of partnering with customers and other stakeholders during this process to ensure the timeous resourcing of projects with people, material and equipment. This strategy facilitates quality project delivery, safely, on time and within budget. We utilise up to date estimating, accounting and project control software.